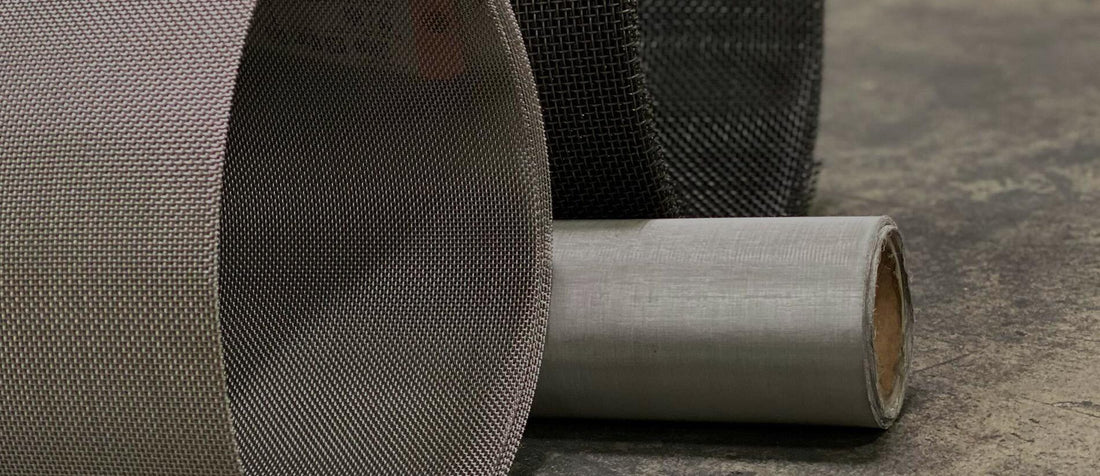

Wire Mesh vs. Wire Cloth

When it comes to materials used for filtration, separation, reinforcement, or even decorative purposes, both wire mesh and wire cloth are common options. At first glance, these terms might seem interchangeable, but there are distinct differences between the two. This article explores the key differences between wire mesh and wire cloth, their unique characteristics, and the best applications for each.

What is Wire Mesh?

Wire mesh is a material made by interlocking metal wires through various methods like welding or weaving. The wires are arranged in a grid-like structure, creating a rigid, durable product with uniform openings. Wire mesh is available in a variety of materials, including stainless steel, galvanized steel, and even plastic.

Key Characteristics of Wire Mesh:

• Grid-Like Structure: Wire mesh typically has evenly spaced openings, creating a strong and durable grid.

• Thickness and Strength: Wire mesh tends to be thicker and more rigid than wire cloth, making it ideal for heavy-duty applications.

• Variety of Forms: It can come in forms such as welded mesh, woven mesh, or crimped mesh, depending on the method used to manufacture it.

Applications of Wire Mesh:

Due to its strength and versatility, wire mesh is widely used in:

• Fencing and Security: Wire mesh, especially welded and chain link mesh, is commonly used for fencing solutions, including security perimeters for industrial, commercial, and residential properties.

• Construction: It provides reinforcement in concrete structures and serves as a safety barrier at construction sites.

• Industrial Filtration and Screening: Wire mesh is often used for separating materials, particularly in mining, quarrying, and industrial filtration systems.

• Animal Enclosures: Wire mesh is widely used in agriculture and zoos for animal enclosures, as its rigidity and strength make it safe and durable.

What is Wire Cloth?

Wire cloth, also known as wire fabric, is similar to wire mesh in that it’s made from interwoven metal wires. However, wire cloth typically uses finer wires and is more tightly woven than wire mesh, resulting in a more flexible and delicate material. Wire cloth is often used when precision filtration or a more refined finish is required.

Key Characteristics of Wire Cloth:

• Finer Weave: Wire cloth uses finer wires that are closely woven together, creating smaller openings than most wire mesh types.

• Flexibility: Wire cloth is more flexible and can easily bend and conform to various shapes, unlike the rigid structure of wire mesh.

• Precision Openings: Wire cloth is often used when precise filtering or separation of particles is required, thanks to its tightly controlled openings.

Applications of Wire Cloth:

Due to its fine weave and flexibility, wire cloth is suited for more delicate applications such as:

• Fine Filtration: Wire cloth is ideal for filtering small particles from liquids or gases in industries like pharmaceuticals, food processing, and chemical manufacturing.

• Sieving and Separation: In laboratories and industrial settings, wire cloth is used for sieving fine materials, such as powders or granular substances.

• Electrical Shielding: The fine weave of wire cloth makes it suitable for electromagnetic interference (EMI) shielding in electronics.

• Decorative Uses: Wire cloth’s finer, more delicate appearance can also be used for interior design applications, such as screens, grilles, or decorative panels.

Comparison: Wire Mesh vs. Wire Cloth

| Feature | Wire Mesh | Wire Cloth |

| Structure |

Grid-like structure with thicker wires |

Tightly woven with finer wires |

|

Flexibility |

Rigid and sturdy |

Flexible and bendable |

|

Material Thickness |

Thicker wires, often for heavy-duty applications |

Finer wires, suited for precision tasks |

|

Applications |

Security, fencing, construction, industrial use |

Filtration, sieving, decorative, electrical uses |

|

Common Forms |

Welded mesh, crimped mesh, chain link |

Woven wire cloth |

Choosing Between Wire Mesh and Wire Cloth

When deciding whether to use wire mesh or wire cloth, consider the specific requirements of your project. Here are some factors to keep in mind:

1. Strength and Durability:

If your project requires a strong, rigid material for heavy-duty applications like fencing, construction, or industrial sieving, wire mesh is the better option. Its thicker wires and grid-like design provide extra strength and stability.

2. Flexibility and Precision:

If flexibility or fine filtration is needed, wire cloth is the ideal choice. Its finer weave makes it excellent for separating small particles, sieving fine materials, or applications where precise control over openings is required.

3. Aesthetic and Decorative Use:

While wire mesh can also be used for decorative purposes in architecture, wire cloth offers a more refined and delicate appearance, making it suitable for interior design elements like grilles and screens.

4. Application Environment:

Both wire mesh and wire cloth are available in various materials, such as stainless steel, copper, and aluminum, making them suitable for different environments. For example, stainless steel wire cloth is often used in harsh chemical environments due to its corrosion resistance, while galvanized wire mesh is commonly used outdoors for its ability to withstand the elements.

Conclusion

Both wire mesh and wire cloth are versatile materials with a wide range of applications. While wire mesh is favored for its strength and rigidity in heavy-duty tasks, wire cloth excels in precision filtration and flexible applications. Understanding the differences between the two will help you select the right material for your project’s specific needs.

Whether you’re building a secure fence, reinforcing concrete, or filtering delicate materials, choosing between wire mesh and wire cloth is essential for achieving optimal results. Evaluate the strength, flexibility, and purpose of your application, and you’ll make an informed decision that ensures success.

This article highlights the differences and applications of wire mesh and wire cloth, offering a clear guide for those deciding between the two. Let me know if you’d like any adjustments!